Up to 42% of an active drug can be lost through common crushing activities, a study comparing devices and methods has found.

Via a validated UV method, researchers from University of Queensland used a white, round and scored immediate release 500 mg paracetamol tablets to determine quantity of active drug recovery for delivery to patient and amount leftover in the device. They tested commercially available drug crushing devices with the retrieval methods of tapping out, rinsing with two lots of water, or mixing with additives such as honey, apple sauce or yoghurt for delivery to patient.

Devices included in the study included: Manual tablet crushing devices which involved either lifting a lever up and down, or the use of a twisting action to grind the tablets; electronic grinding devices; as well as mortar and pestles in porcelain, glass and agate.

When the powder was tapped out, drug loss ranged from 1.9 to 13.7%, with at least 95% of the paracetamol being recovered by only 11 out of the 24 devices tested. Manually operated hand-twist crushers with a serrated crushing surface, and some devices with disposable bags or cups, were particularly associated with significant losses.

For crushing devices with disposable bags, an average 6.6% was lost. Each device was supplied with a specific bag, five of which were 0.15–0.18 mm thickness polyethylene bags, which became dented during crushing, trapping powder when trying to tap it out.

Depending on the crusher, of devices that had a vessel with the potential to be used as a drinking cup, the use of one rinse of water recovered between 57.5% and 94% of the dose. The average loss was 24.2%, ranging from 6% with a ball and socket device and up to 42.5% for an electric pill crusher.

With up to 99% of drug recovery in another study attained by rinsing with 100mL of water, the authors said, ‘to minimize drug loss, we recommend that water is added to the crushed tablet in the crushing device or disposable vessel and consumed directly from the device or vessel, with a second rinse being essential’.1

However, it was noted that recovering drug through rinsing increased nursing workload burden and was not always achievable, as some patients were using viscous foods to ingest their drugs due to dysphagia.

The active drug recovery in this study by using yoghurt and apple sauce was 95.2% and 93.7% respectively – however, both were at the same level as rinsing twice with water. Use of honey reduced drug delivery to 83.9%.

The agate mortar and pestle produced very low drug loss (2.3%), when the powder was tapped out; porcelain or glass produced losses of between 4.1–4.7%. However, it was noted this method in particular produced high aerosolisation of the crushed drug, which could lead to allergic reaction or toxic inhalation, particularly with chemotherapy drugs. This also presented an issue with other devices in uncontained spaces.

Pharmacists can refer to the manuscript on Crushing, dispersing or repackaging medicines in the APF24 for guidance when making a decision whether to modify dosage forms.

The handbook Don’t Rush to Crush is the essential guide for pharmacists, nurses and healthcare professionals giving oral medicines to people who have swallowing difficulties or an enteral feeding tube. PSA offers it with the eMIMSCloud as a digital bundle.

The full article is available here.

References

[1] Thong MY, Manrique YJ, Steadman KJ (2018) Drug loss while crushing tablets: Comparison of 24 tablet crushing devices. PLoS ONE 13(3): e0193683. https://doi.org/10.1371/journal.pone.0193683

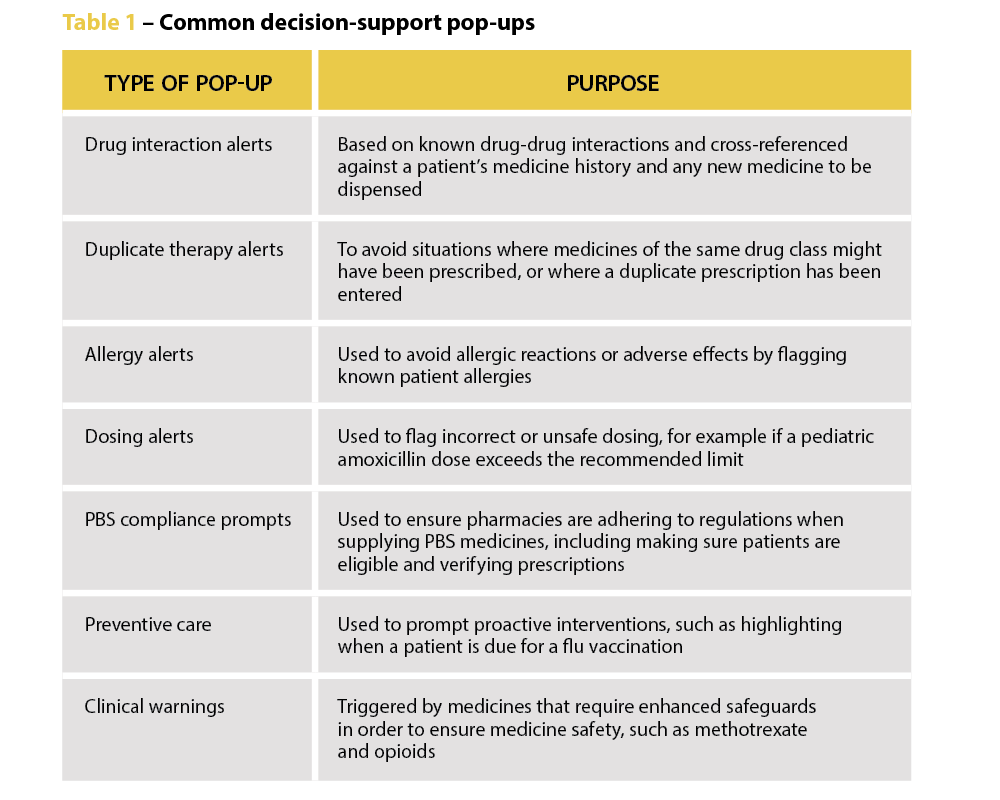

‘We’re increasingly seeing incidents where alert fatigue has been identified as a contributing factor. It’s not that there wasn’t an alert in place, but that it was lost among the other alerts the clinician saw,’ Prof Baysari says.

‘We’re increasingly seeing incidents where alert fatigue has been identified as a contributing factor. It’s not that there wasn’t an alert in place, but that it was lost among the other alerts the clinician saw,’ Prof Baysari says.

Beyond the arrhythmia, AF often signals broader pathological processes that impair cardiac function and reduce quality of life and life expectancy.5 Many of these conditions are closely linked to social determinants of health, disproportionately affecting populations with socioeconomic disadvantage. Effective AF management requires addressing both the arrhythmia and its underlying contributors.4

Beyond the arrhythmia, AF often signals broader pathological processes that impair cardiac function and reduce quality of life and life expectancy.5 Many of these conditions are closely linked to social determinants of health, disproportionately affecting populations with socioeconomic disadvantage. Effective AF management requires addressing both the arrhythmia and its underlying contributors.4  C – Comorbidity and risk factor management

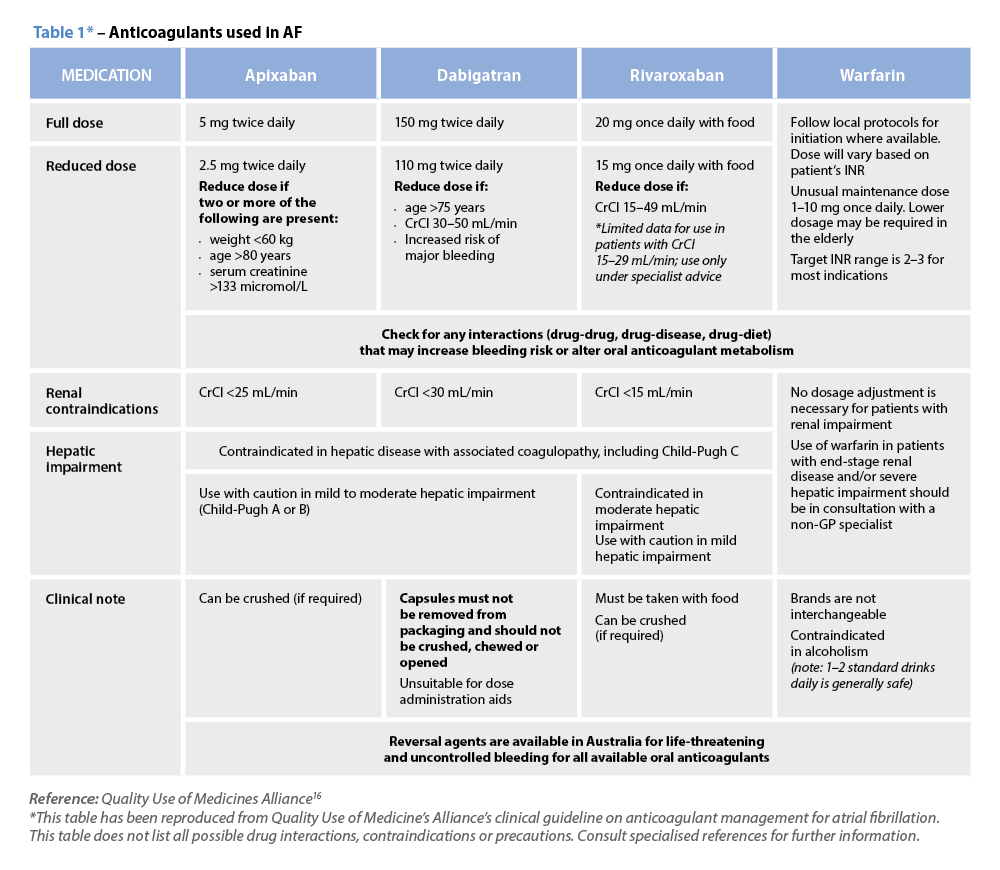

C – Comorbidity and risk factor management Warfarin

Warfarin